Powder Coating Troubleshooting Guide

Chapter Eleven: Powder Curing Process

|

Baking Needs for Powder Coatings

Thermoplastic Powders:

Thermoset Powders:

Although the bake/cure process generally follows after the coating is applied, there are instances when it’s preferable to heat the substrate first.

|

Factors Affecting Cure

Recommended cure times are based on time at METAL TEMPERATURE. |

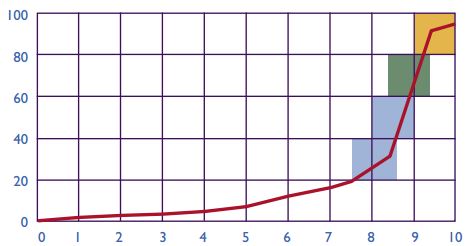

Stages of Cure Development

Melt point:

- Powder particles begin changing from a solid to semi-liquid state.

Flow stage:

- Powder is fully liquefied, reaching lowest viscosity, allowing film to smooth out

Cross linking stage:

- Sufficient, sustained heat triggers large scale reaction within film, initial steps to total chemical/physical change of product

Gel stage:

- When sufficient crosslinking has occurred, for solidification of the film from a liquid to a solid

Cure development:

- The final, and most critical stage when baking results in reaction of majority of crosslinking sites and development of full design properties

Typical Cure Development

| % Cure Properties |  |

| Cure Time (minutes) |

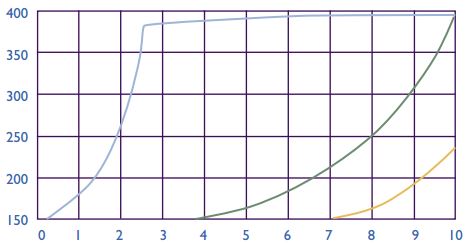

Importance of Metal Thickness

| Metal Temperature (°F) |  |

| Oven Time (minutes) |

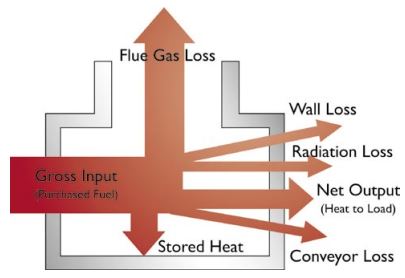

Bake Oven Designs and Energy Consumption

|

|

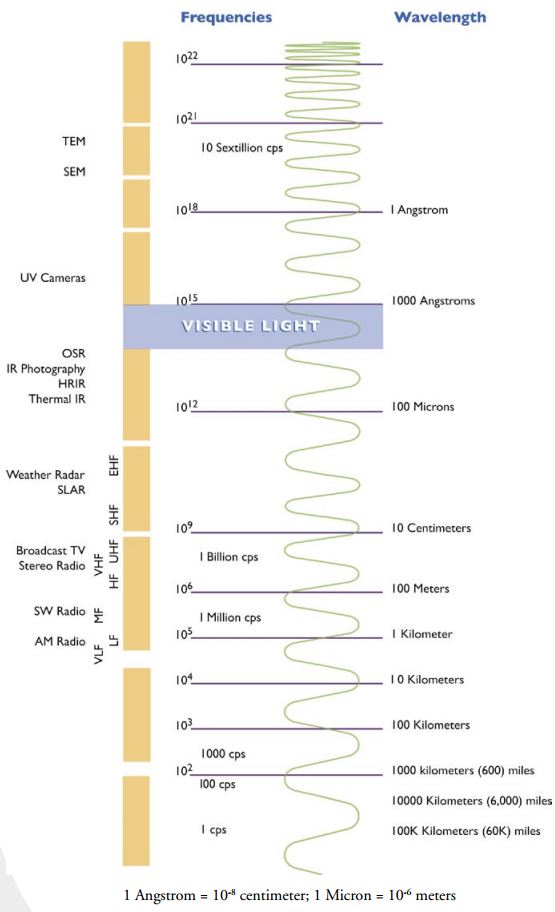

IR Curing Sources

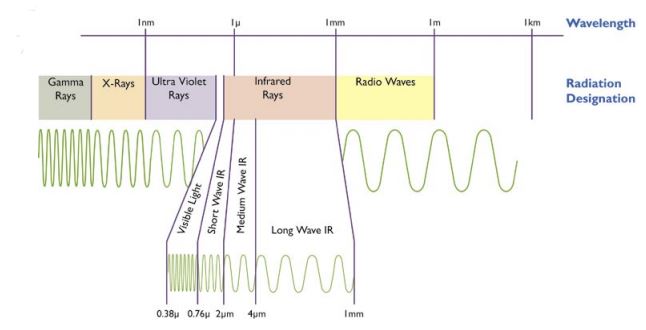

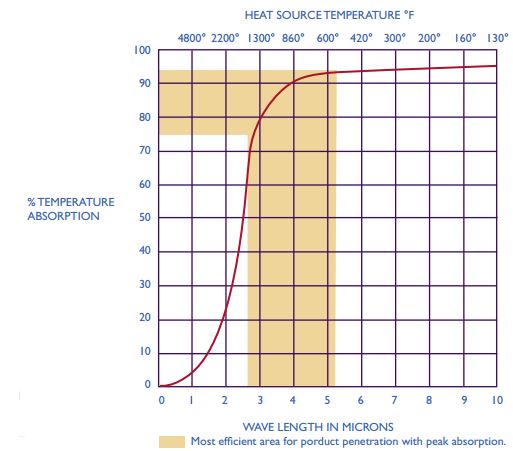

Different wave lengths have different curing properties to be considered.

|

The Frequency Spectrum

The Frequency Spectrum

Optimum Infrared Wave Lengths

Other Chapters

- Early Powder Coatings, Uses, and Types

- Manufacturing of Powder Coatings

- Powder Chemistries, Formulations, Comparisons, and Uses

- Comparisons to Liquid Coatings

- Measuring Up the Product

- Pretreatment

- Powder Application Methods and Equipment

- Powder Coating Recovery Equipment

- The Electrostatic Charge Process

- Powder Application Tips

- Safety Issues With Powder Coatings

- TCI Troubleshooting Guide

- Glossary of Industry Related Terms