Powder Coating Troubleshooting Guide

Chapter Nine: The Electrostatic Charge Process

- Typical voltages of 40,000 to 100,000 VDC.

- Typical currents of 15-60 Micro amps

- One milliamp is 1/1,000th of an amp and would cause a small but noticable shock

- One micro amp is 1/1,000,000th of an amp and would cause no sensation at all.

- 15-60 micro amps will not harm humans though extended exposure might cause tickling sensation-similar to a carpet shock.

- Symbol for Micro amp is: µA

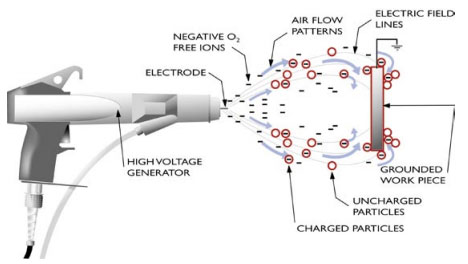

- The corona field creates field lines of force coming out of the gun which converge on sharp edges and points.

- Free electrons follow the lines of force.

- The electrons hit air molecules splitting them into 2 more electrons and 1 ion.

- New electrons hit new air molecules

- Free ions travel towards the source.

- Ions also hit and split air molecules.

|

Corona Charging of Powder Particles

|

Corona Charging Particle Saturation

|

Several forces act on the moving particle to deliver and deposit it on the part: air resistance, aerodynamic force, electric force, and gravity. Importantly electric force can only complete its function if the product substrate is properly grounded.

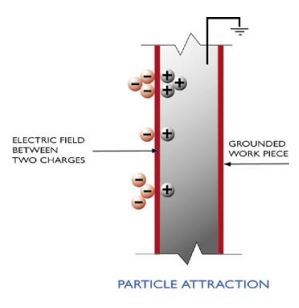

Electrostatic Attraction of Powder at the Substrate Surface:

Electric Deposition of the Powder:

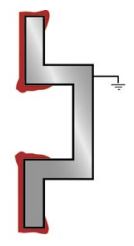

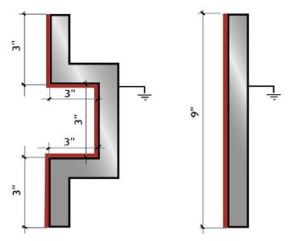

Back Ionization: Back ionization is caused primarily when the part has reached the saturation point at which no additional powder can be attracted to the substrate. Indications may be:

As powder continues to be deposited on the part, the strength of the electric field within the powder layers increases because each new particle:

If spraying continues beyond the saturation point, the electric field within the film will become high enough to:

Adjustments for back ionization include:

|

|

|

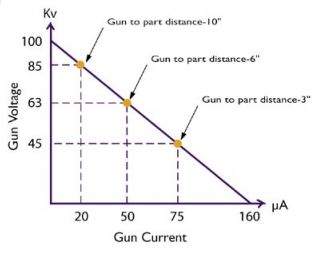

Current Output

|

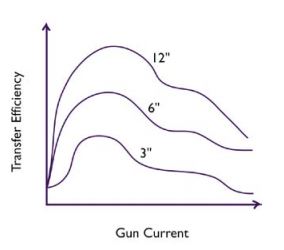

Transfer Efficiency vs. Gun to Part Distance

|

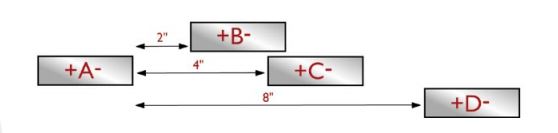

Attractive forces are inversely proportional to the square of the target distance.

| FORCE = |

I |

A to B = 2" (1/(2x2) = 0.25 or relative force =16

A to C = 4" (1/(4x4) = 0.0625 or relative force = 4

A to D = 8" (1/(8x8) = 0.0156 or relative force = 1

|

|

|

|

|

|

|

|

The charge developed by a powder particle is a function of the charge to mass ratio. This ratio is inversely proportional to the radius of a particle. Larger particles charge less efficently. A (one) 1 mil particle has 1/512th the mass of an 8 mil particle, but the total volume of smaller particles making up that mass will carry 8 times the charge due to the increased surface area.

| Base Size | Number of Particles | Surface Area |

| 8 Mils | 1 Particle | 1 Unit |

| 4 Mils | 8 Particles | 2 Units |

| 2 Mils | 64 Particles | 4 Units |

| 1 Mil | 512 Particles | 8 Units |

Current limiting devices were developed to help minimize back ionization and are particularly suited for automatic guns where constant adjustments are impractical. As the air space between the gun and part decreases, the resistance also decreases, therefore the current increases proportionately. With a higher current, more and faster free-ions are generated. Higher current causes the part to reach saturation and back-ionization making it more difficult to build film and coat recess. These devices assist in reducing Faraday cage effects and help maintain optimum field strength and gun current between the electrode and parts.

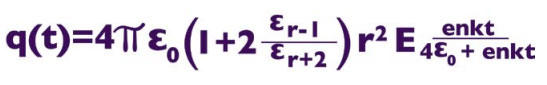

The ability of powder particles to develop a charge while passing through a corona field is governed by Pauthenier’s equation.

WHERE

r = Radius of particle

E = Field strength

e = Charge of an electron

k = Electron mobility

n = Electron concentration

t = Time

?? = Absoulute permittivity

?r = Relative permittivity of powder material

The amount of charge is directly proportional to the field strength geometry and the square of the particle radius. It is also affected by the particle and the amount of time in the charge zone.

Other Chapters

- Early Powder Coatings, Uses, and Types

- Manufacturing of Powder Coatings

- Powder Chemistries, Formulations, Comparisons, and Uses

- Comparisons to Liquid Coatings

- Measuring Up the Product

- Pretreatment

- Powder Application Methods and Equipment

- Powder Coating Recovery Equipment

- Powder Application Tips

- Powder Curing Process

- Safety Issues With Powder Coatings

- TCI Troubleshooting Guide

- Glossary of Industry Related Terms